Manufacturing Industry: Impact of Robotics in Dispensing Technologies

There are certain industries where accuracy plays a vital role in the forward movent of a company, and manufacturing is one of those industries. A lot of the operations and processes within manufacturing rely heavily on manual dispensing of fluids and adhesives. Well, being so reliant upon manual dispensing was getting the job done but it also posed a plethora of other issues… but the major issue was dispensing inaccuracies.

Have you ever tried to pour water in a glass and then tried to pour that same amount of water in another glass? It never really measured out the same, did it? More than likely not. And that’s the issues that the manufacturing industry encountered with manual dispensing.

For certain applications, manual dispensing works but for other applications, where accuracy is a must, manual dispensing isn’t the solution… If you think about it… the quality of a dispense is only as good as how well the operator dispenses it. This is when you start to get into the area of human error versus robotics, which then gives way to this theory where robots are going to take over the world.

Robots vs. The World

People have long thought that robots would soon be taking over the world for quite some time. Everything from Rosie, the robotic maid from the early 1960’s popular cartoon series The Jetsons, on up to the human-like robots from the movie I, Robot, people pictured these pieces of metal living and interacting like humans, soon ending the entire race (people watch too much TV and movies).

What people fail to realize in their senseless fear is that these pieces of technology have to be programmed by humans in order to perform the functions they do. So unless someone programs a robot to destroy mankind, humans can breathe a little easy.

Now, one area where people are getting a little nervous is that robots will outperform humans and threaten their job security. According to CNBC, the reality of robotic technology is that there isn’t one job sector that won’t be impacted by technological changes… robots are flooding almost every US industry, and not just manufacturing either! In fact, did you know that you can get a cup of coffee made by a robot barista! That just goes to show you that no one is safe!

But all kidding aside, robots aren’t here to ruin the lives of hard-working people… they’re here to improve the lives of hard-working people, especially in areas of manufacturing where accuracy is crucial. So it’s not robots versus the world… it’s really how robots are helping the world.

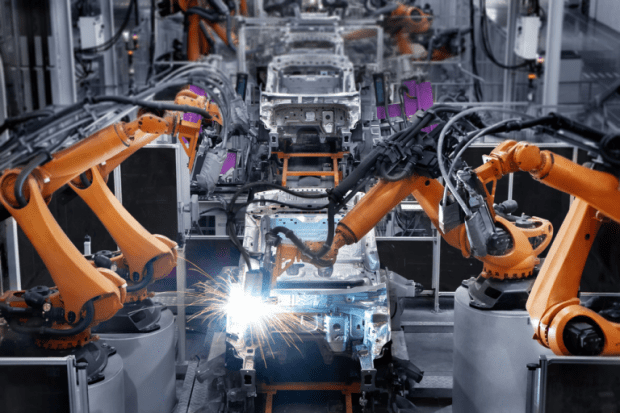

How Robots are Positively Impacting the Manufacturing Industry

Companies that are looking to improve dispense quality turn to bdtronic dispensing technology. This ensures that the dispensing is always the same when adhesives are within specifications, plus, you will see an increase in productivity, efficiency, and less waste, which will not only contribute to better overall quality but it will also produce a bigger ROI at a faster rate because work is being done quickly and more efficiently.

Now you might be wondering, if dispensing technologies are such a great benefit to the manufacturing industry, how much will it cost? Well, costs vary from company to company but you can guarantee that investing in dispensing technology is not only a good investment but it’s also a smart business move.

Just think about all the money you can potentially lose just in waste and rework from dispensing inaccuracies. Robot dispensing is going to give you product precision and ultimately reduce and nearly wipe out the likelihood of human error.

If you’re completely clueless about robotics in manufacturing, you’re probably going to be thinking of the robots that look like humans but aren’t humans… If that’s what you’re thinking, just completely get that image out of your head… When it comes to robotics in manufacturing, you’re going to want to look at the type of dispenser a manufacturer will be using and the type of robot that will be in control of the dispenser.

Unlike Rosie the robot, manufacturing robots are defined and utilized based on how many axes they have. Robots that only move up/down and left/right, are robots with only two axes. Now, robots that move side to side, front to back, left/right, and up/down, are robots that have three axes. If a robot has four or more axes, then you have a robot that can perform all of the above, plus rotations.

Robots actually play a significant role in several industries but the manufacturing industry relies heavily on robotics to reduce human error and improve accuracy. Now, just because robots have proven to be very beneficial to several industries, that doesn’t mean you should feel threatened for your job security. The reality behind robotics, especially in dispensing technologies, is to make your jobs easier. Once workers can embrace it, work will go much smoother.